Materials and Connectors

This is a subject that not many websites cover and it`s a questions that keeps coming up on Tesla coil mailing lists and social media.

Questions like "How do I connect the top load" or "What should I use to build my coil".

This page is going to be a kind of catch all, there are no hard and fast rules it all depends on what is avalibe to you, how much you want to invest in materials, if it works then use it BUT you might be leaving some performance off the table this page is going to quite "wordy"

Questions like "How do I connect the top load" or "What should I use to build my coil".

This page is going to be a kind of catch all, there are no hard and fast rules it all depends on what is avalibe to you, how much you want to invest in materials, if it works then use it BUT you might be leaving some performance off the table this page is going to quite "wordy"

Ground connection

DO NOT USE YOUR HOUSE GROUND - a good solid outdoors ground connection is the best way to go, we have a 1m grounding rod hammered in to the ground with a 2m copper strip attached just under the surface, this ground rod is attached to the base of the secondary with the thickest cable we could find to reduce and keep the resistance as low as possible.

Coil component connections

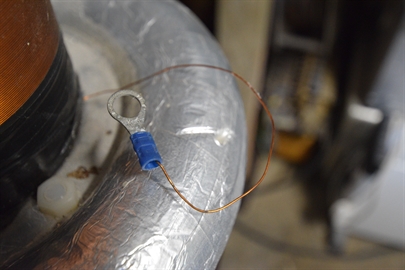

Again we use nice thick copper cable, automotive battery cables are great for this as they come with zinc/copper eyelets pre-installed and come in different lengths, they can be expencive but the ease of use is fantastic, if you visit your local scrap yard you might find some industrial electrical equipment that has high current cable that are able to be removed - we were lucky some years ago to be able to source a load of these types of cables.

When it comes to the bolts we try and use Brass everywhere possible, Brass does not heat up as much as steel and can be easer to work with, again Brass fittings can be expencive but they help with a little performance and look good.

When it comes to connecting the secondary to the ground connection or the secondary to the top load - a simple eyelet will do just fine just crimp these on - job done

In simple turms is it ment to conduct voltage and current use brass and copper but if it`s not a conductor try and use plastic/nylon nuts and bolts

Insulators and stand off`s

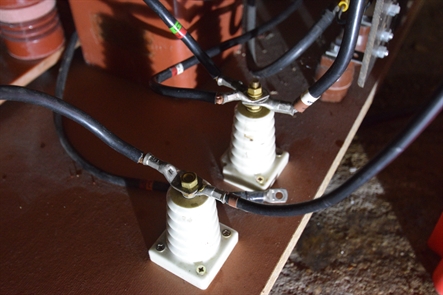

Again we are trying to keep everything separat, high voltage does have a nasty nack of finding weak spots in your build, you can find ceramic insulators on Ebay but these can be expencive, if you can afford such things very high voltage insulators can be sorused from verious companys but again these can be very expencive but help with the overall look and work fantastly well, we purchased some 40Kv insurlators from Germany and look and work great for our 400bps rotary spark gap.

If you can`t find or afford these type of insurlators you can always build your own, we sourced a 1m lenght of Nylon rod from RS components and made thes ourselfs, cut to lenghts and you can fit a thredded inset to help with bolting every thing down.

Rotary spark gap disks

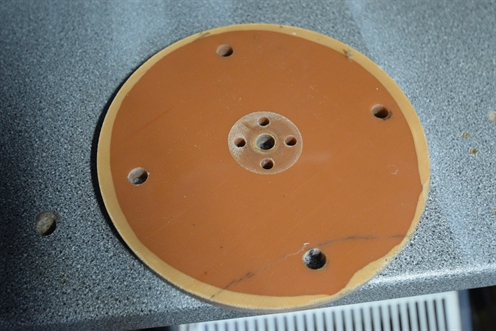

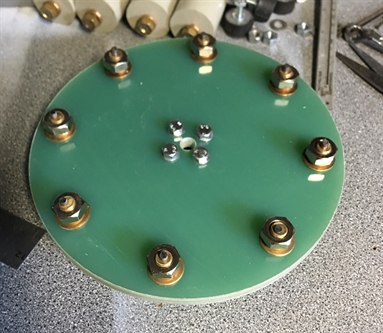

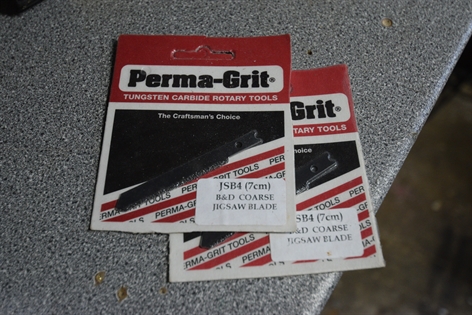

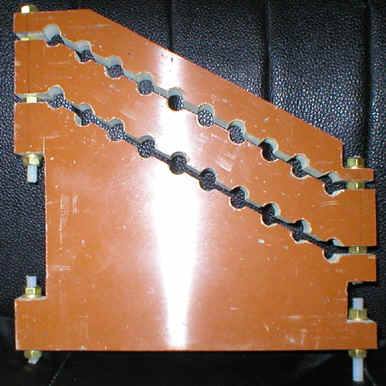

When it comes to the disk for your rotary we are looking for a meterial that is a good electrical insurlator and a materiel that has very good structual strengh, to this end we have in the past used Tuffnol (Carp or Whale) brands it`s relitivly cheep to get hold of and easy to work with, if you want to move up a step you can use a meterial called G10 this is a gless/epoxy and its very had (it will eat brill bits and jigsaw blades, the best way to cut the stuff is to use Tungstern carbide cutting tools.

Just a word from past experiance do not use wood as your rotary dick will burn and carbon track very quickly - been there - done that.

Just a word from past experiance do not use wood as your rotary dick will burn and carbon track very quickly - been there - done that.

The above 2 disks are G10 Glass epoxy, to the right are the Tungstern carbide cutting blades used in my Jigsaw to rought cut the disks

Primary surport materials

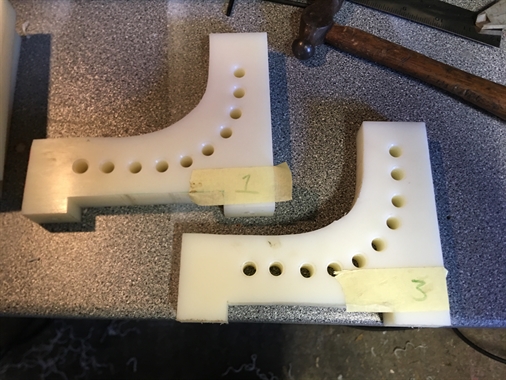

Again we are looking at materials that are cheep, easty to find and easy to work with, remember again high voltage has a way of finding any weak spots in your built - wood is not great but you can help things along by coating it with many layers of good qulity varnish, or just use acrillic, plexiglass, tuffnol we have used all of these over the years, the last primary surports were made out of Nylon6 a great non conductor and very hard as always every thing is held together with Nylon nuts and bolts.

Below left - Nylon6 and on the right Whale brand Tuffnol

Below left - Nylon6 and on the right Whale brand Tuffnol

Primary coil tap connector

Over the years people have come up with ingenius ways to connect the tank supply to the primary coil, in the past we used a large crocadile clip with the inner teeth removed so it was a tight fit around the primary, for the last few years we have used nothing more complicated than a fuse holder, if you get the right size it will clip nice and tight to the primary.

Copy right 2022